In this experience, I worked with a team to design and make 50 cupcake themed yo-yos using thermoforming and injection molding fabrication. Through this process I learned design for manufacture and assembly (DFM/DFA), process optimization, CNC machining, injection molding and thermoforming. 3D printed and aluminum molds were used to make thermoformed and injection molded parts. During the semester I designed the cupcake cake thermoform mold, the cake mold for injection molding, and optimized the design and machine settings for both injection molded components. To see more about this project please visit our website: https://sweettooth-yoyo.blogspot.com/

Cupcake themed yo-yo

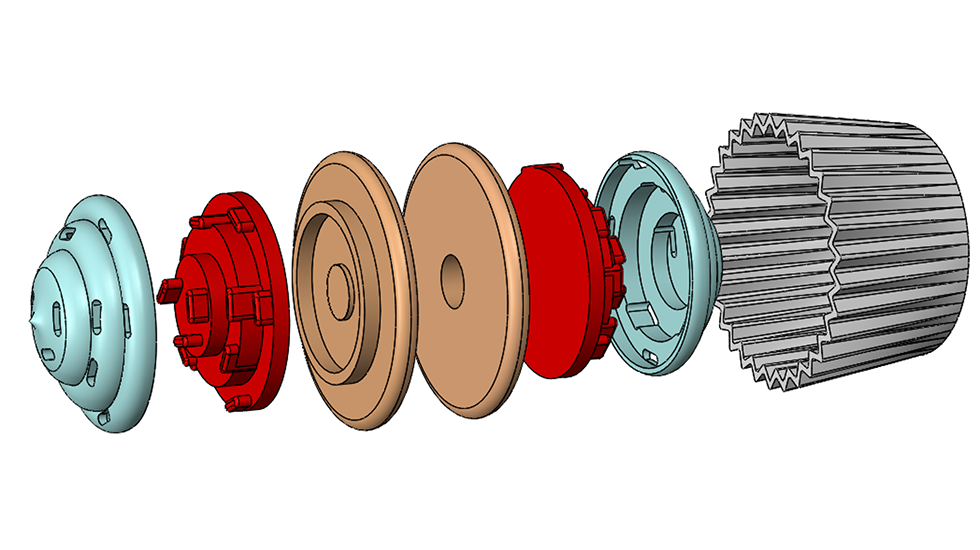

Exploded view of the assembly showcasing the four different components: injection molded cake and frosting and thermoformed sprinkles and cup

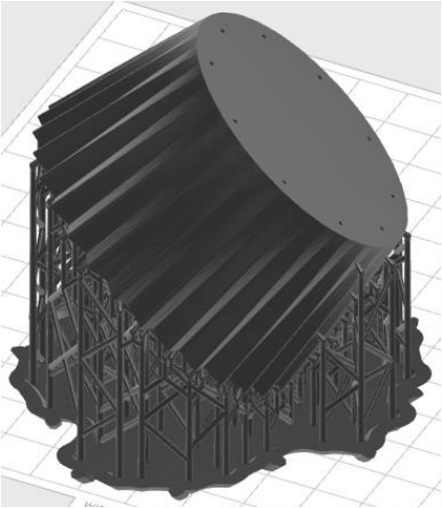

The sprinkles and cup thermoform molds were made using an SLA printer

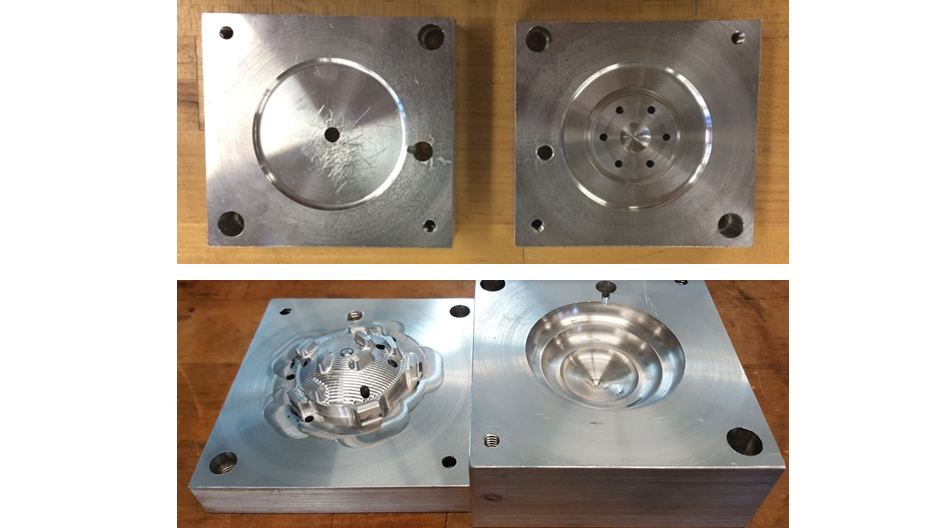

Cake and frosting molds, made using CNC mill and lathe

Sprinkles were thermoformed using both the male and female molds to eliminate webbing between the sprinkles and achieve the desired height

Due to the height of the cup a plug assist was used to draw the plastic sheet to the sides of the mold and create a vacuum seal on the bottom

Completed individual components with frosting injection molded in different colors and hand painted sprinkles